SOLUTIONS

Research and development

At ADAXIS, we collaborate with a large number of world leading companies and universities driving innovation and research in robotics, additive manufacturing, and computational geometry.

RESEARCH PROJECT

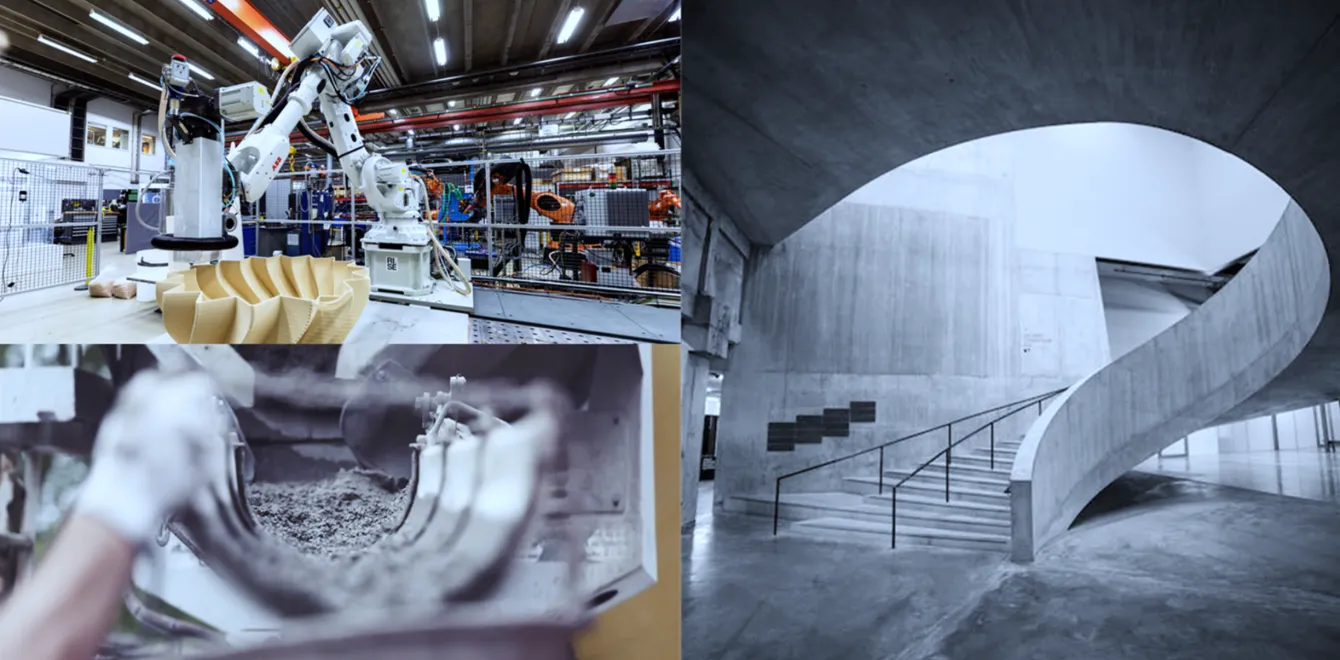

Sustainable Steel Manufacturing (SESAM)

This project is a continuation of previous research at University West where the Laser Directed Energy Deposition with wire (L-DEDw) technique was developed and validated for duplex stainless steel.

In the SESAM project, the L-DEDw process are further developed with support from Procada, Adaxis and Voestalpine Böhler Welding in order to facilitiate industrialization. The project will expand the application range of the L-DEDw process by manufacturing additional component geometries for Alfa Laval with the goal to ensure competence development and enable the technology’s implementation for production.

Project partners

Funding

Vinnova (Swedish Agency for Innovation Systems)

RESEARCH PROJECT

3D printing of Sustainable Prefabricated Concrete Elements (PrintCrete)

The PrintCrete project advances 3D concrete printing for cost-effective and efficient construction in Sweden. It focuses on material development, process refinement, and sustainable business models, aiming to overcome current limitations and promote widespread adoption of 3D concrete printing.

PrintCrete innovates 3D printing by adapting proven techniques from polymers and metals to concrete. It emphasizes prefabrication to accelerate industrial adoption and optimizes value chains by involving stakeholders and analyzing implementation risks for market alignment and customer satisfaction. The project also consolidates knowledge, conducts real product demonstrations, and explores broad applications across various construction sectors, with the potential to make complex components competitive for production using these techniques.

Project partners

Funding

Formas – Smart Built Environment

RESEARCH PROJECT

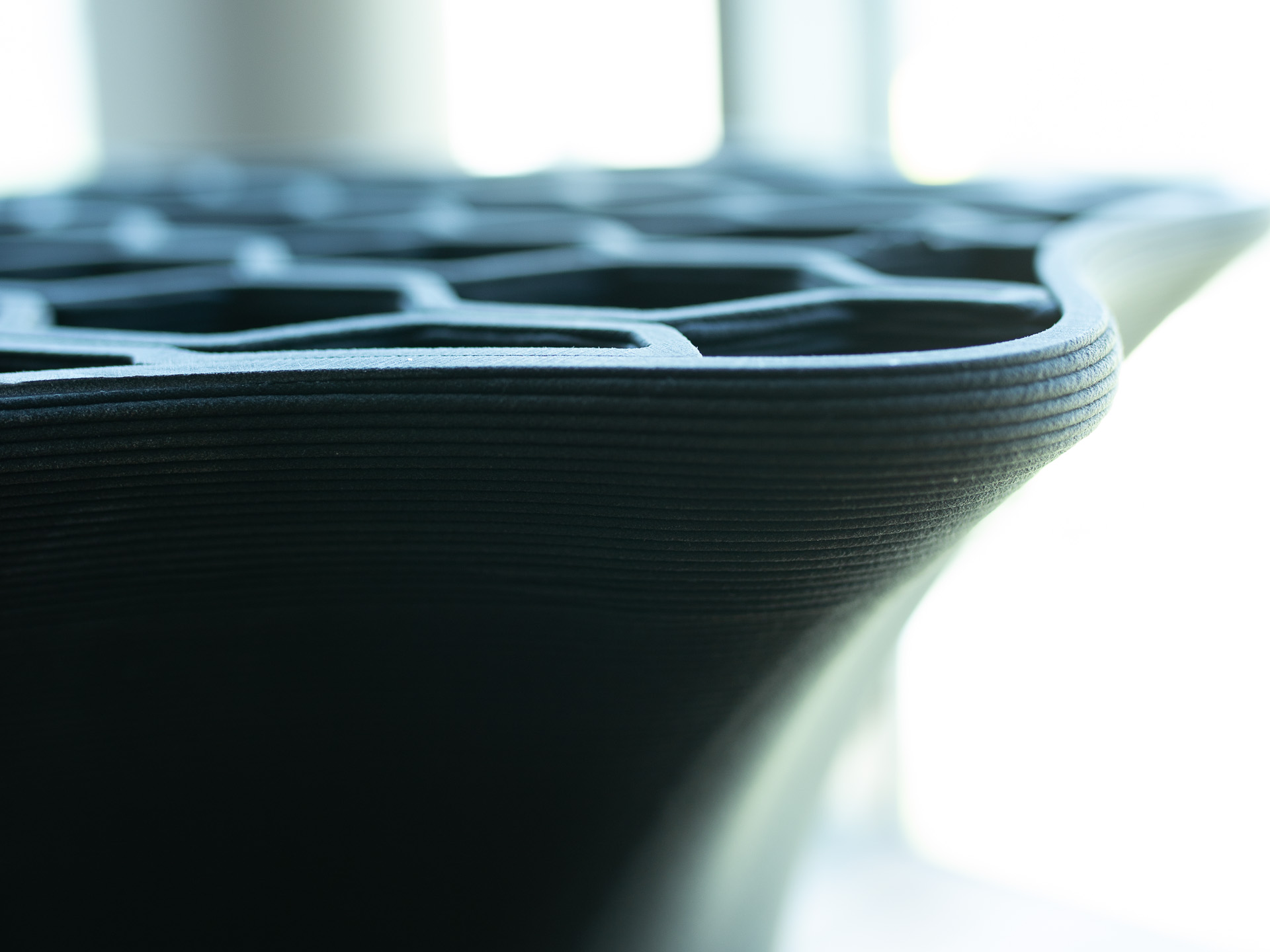

Developing sustainable and resilient circular economy microfactories (SuRF-LSAM)

This project focuses on enabling circular production that brings Large Scale Additive Manufacturing (LSAM) technology closer to customers, using a microfactory or a mobile “factory-in-a-box” concept. The microfactory concept involves sorting, shredding, recycling waste materials into secondary raw materials, and producing new parts on-site using LSAM technology.

The project will establish two LSAM microfactories, one in Peniche, Portugal, and one in Stockholm, Sweden.

LSAM microfactories using recycled polymers offer flexibility, sustainability, and resilience, particularly in the face of uncertainties like raw material shortages, pandemics, wars, and natural disasters.

Project partners

Chalmers Uni. of Tech., Research Institutes of Sweden, Add:North, Artex, Brandworks, Ekbacken Studios, PaperShell, The INDUSTRY Sweden, AGIX, Ocean Tech Hub, Penimar, Polytechnic Institute of Leiria (IPL), Centre for Rapid and Sustainable Product Development (CDRSP), ScalesOceans, University of Coimbra, Civil Engineering Department, Portugal.

Funding

VINNOVA | Production 2030

Explore other applications