Metal additive manufacturing of large scale parts involves tackling several critical challenges, including robotic interpolation, optimized trajectory generation, managing thermal issues, and selecting the correct parameters for flawless first-time printing.

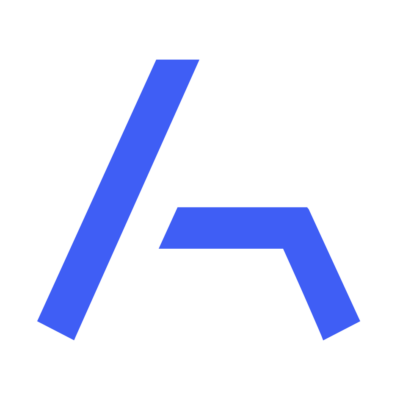

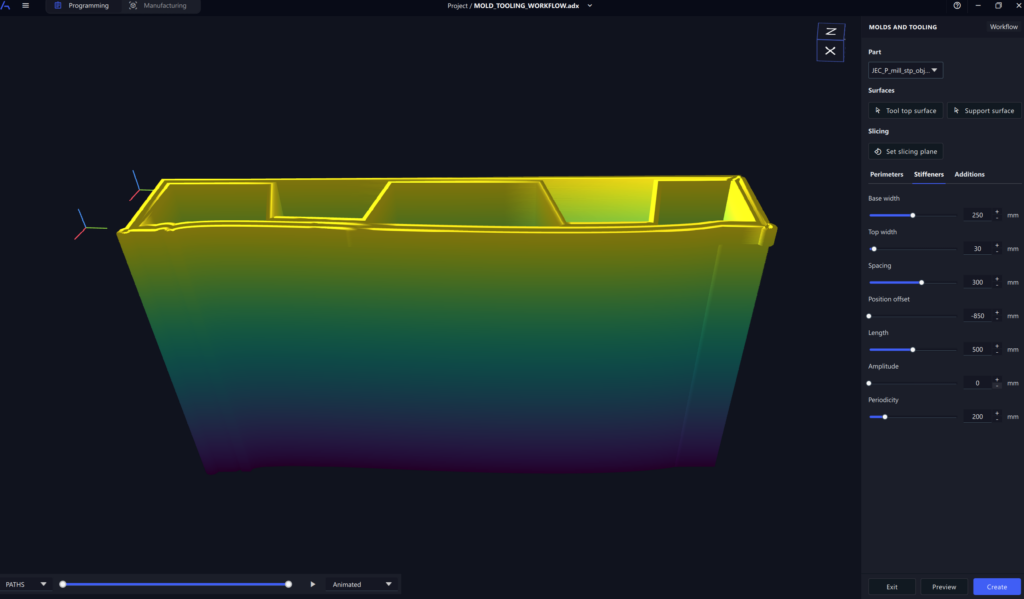

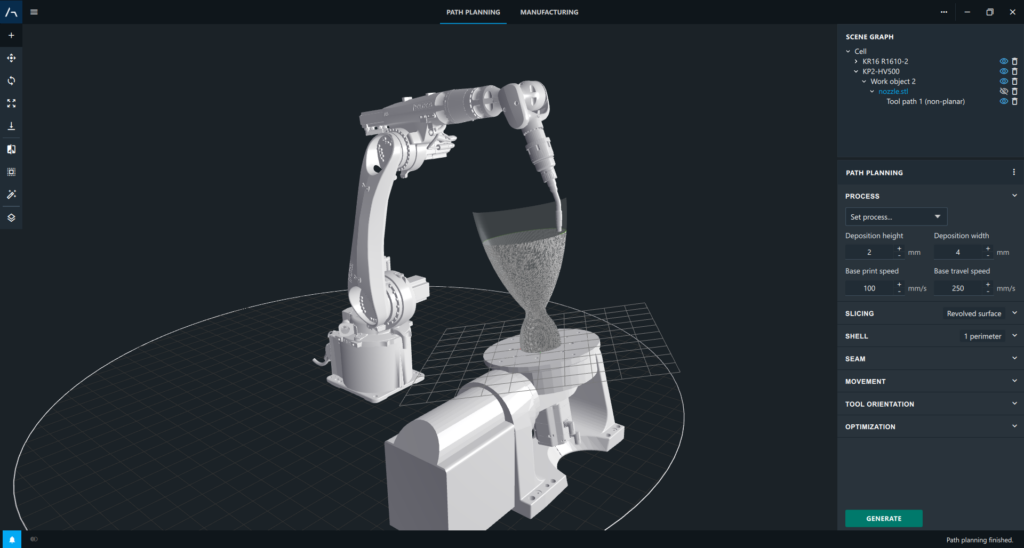

Our partner, Addimadour, has successfully navigated through these challenges, and we take pride in contributing to their success through our software, AdaOne, which facilitates the production of large metal parts through its advanced build styles and flexibility.

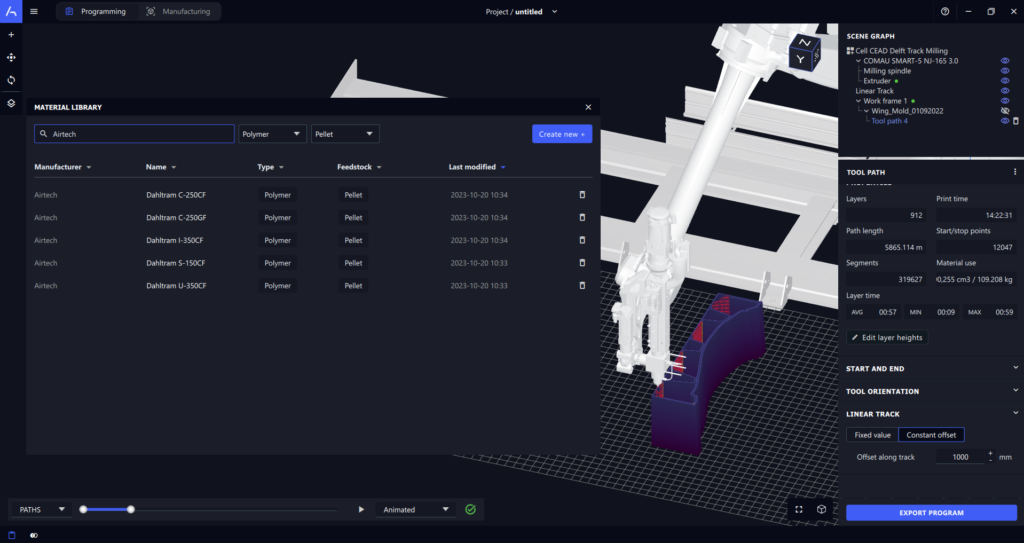

The project’s objective is to create molding tools for composite parts using Wire Arc Additive Manufacturing (WAAM) for the French first-tier aerospace supplier CERTIM, with a primary focus on reducing the environmental footprint in the manufacturing of these essential components.

Beyond significant time savings, this approach transforms the logistics of tooling for companies. It offers local, customized manufacturing with infinite possibilities for modification or repair, as well as for reduced consumption and transportation of raw materials.

As storage and flow challenges become more pronounced, metal additive manufacturing proves well-suited to cut down on carbon footprint by addressing many of these needs.

The project’s receipt of the Eco-Innovation Award from the Basque Country Agglomeration Community is a much-appreciated recognition of our efforts to contribute to a more efficient industry.