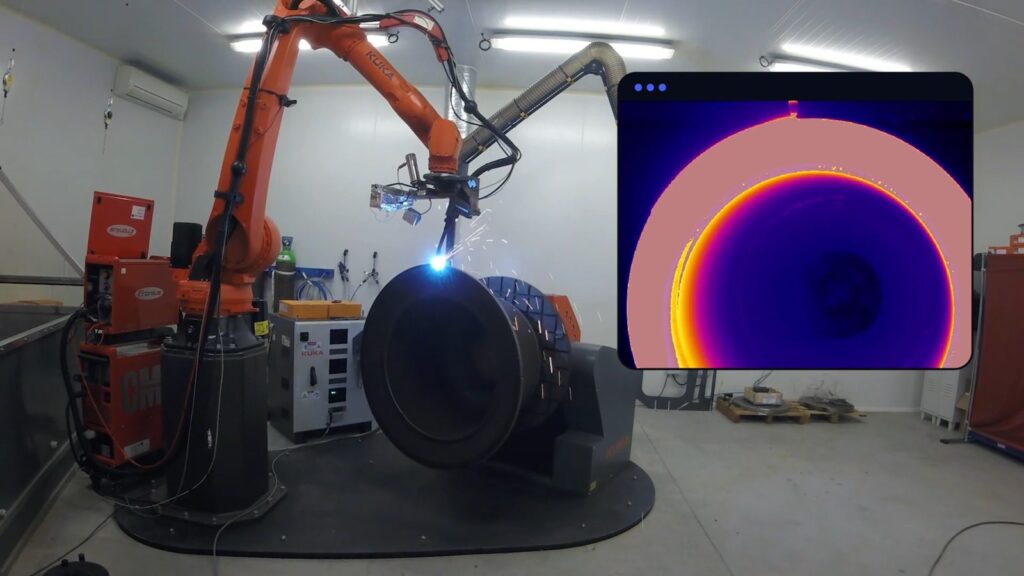

Belotti, a CNC machining solutions pioneer, proudly announces a groundbreaking leap in additive manufacturing for tooling and molds through a strategic collaboration with ADAXIS. This partnership integrates BEAD technology into the AdaOne software, marking a significant breakthrough in manufacturing excellence and democratizing the fabrication of complex large-scale parts.

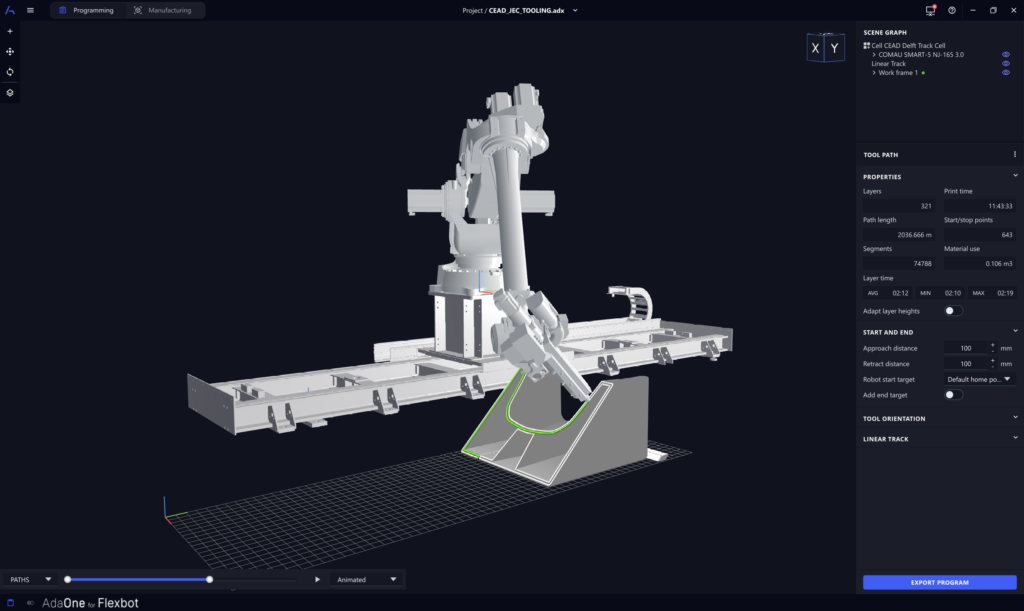

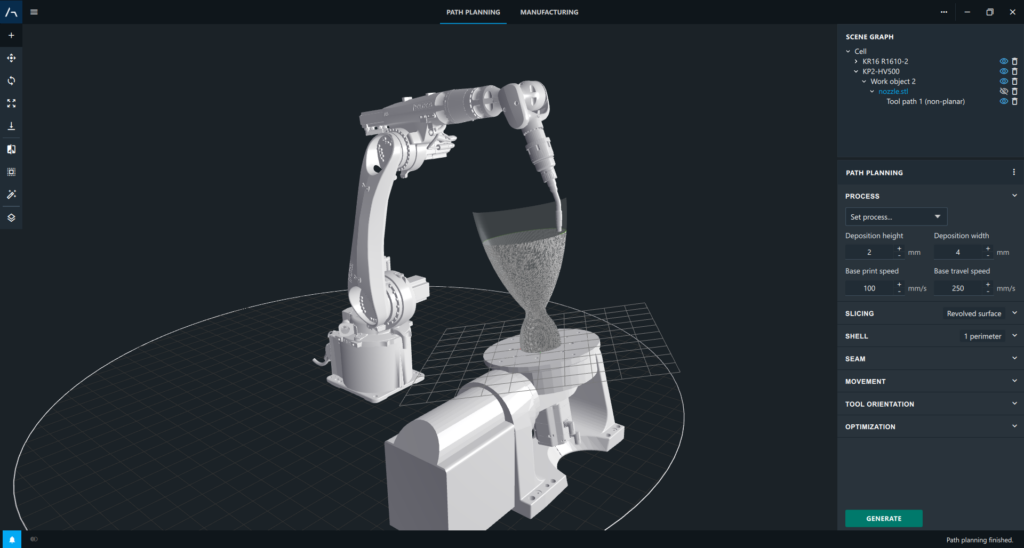

In response to the evolving challenges in manufacturing industries, multi-axis additive manufacturing combined with machining has emerged as a compelling alternative. Belotti, committed to making this technology accessible and cost-effective, initially collaborated with CEAD to bring BEAD to market. Now, partnering with ADAXIS, Belotti aims to deliver a turnkey user experience that simplifies the fabrication of complex molds.

Advancing Tooling and Mold Production

The additive manufacturing process excels in tooling and draping mold production, offering reduced lead times, increased production flexibility, and efficient cost and inventory control. However, effective utilization has traditionally demanded expertise and methodological intricacies.

This collaboration shifts the focus towards user experience, providing simple, robust, and accessible workflows. Operators of any level can now easily program and oversee mold printing from a basic CAD file.

“Partnering with ADAXIS enables us to offer our customers an integrated turnkey solution, comprising seamlessly integrated equipment and software, making our technology and expertise instantly accessible to a broader audience.”

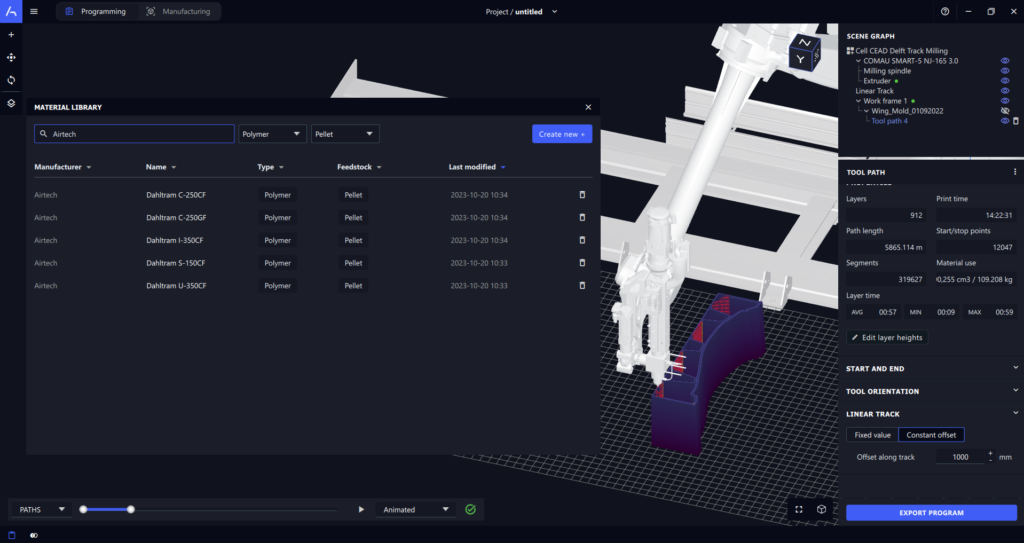

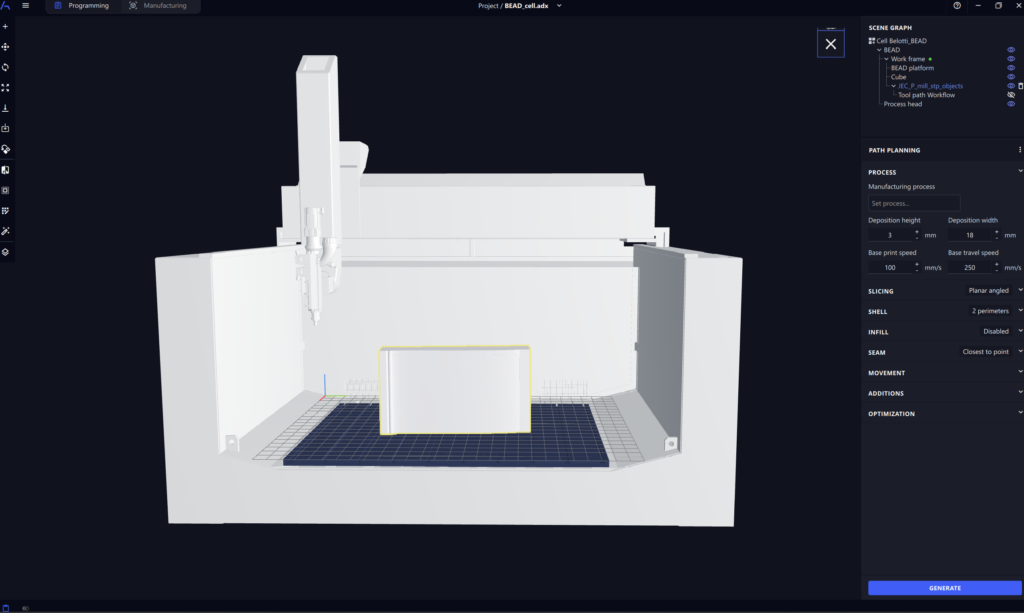

AdaOne introduces a range of unique features tailored for tooling production:

1. Automatic Internal Support: Reduces design time and material usage by the automatic generation of internal stiffeners inside the tooling geometry.

2. Localized Double Bead on Main Surfaces: Generation of machining margin and local reinforcement to facilitate machining of the tooling surfaces.

3. Selective Corner Compensation: Adds extra material at corners to ensure correct final geometry after machining.

4. Continuous Printing Path: Minimizes starts and stops through automatic seam positioning and tool path optimization.

AdaOne also generates machining trajectories, providing operators with a comprehensive turnkey solution.

The AdaOne integration with BEAD technology, supported by Belotti’s expertise, simplifies path programming, reduces material usage, and shortens print time. A collaboration with Airtech ensures that operators receive pre-configured settings tailored to their materials, seamlessly meeting industry standards.

“Collaborating with Belotti’s expert team while applying our expertise in user experience and software development allows us to integrate numerous and unique features into a robust, stable, and industrial-grade solution,” says Emil Johansson, CPO of ADAXIS.