In a groundbreaking collaboration between MTL | More Than Layers and 3DMZ | 3D Makers Zone, two pioneering entities in Haarlem, The Netherlands, the Model.C3 project has emerged as a testament to the fusion of art and technology in the realm of 3D printing.

Model.C3, a fully 3D-printed lounge piece, stands as an innovative creation resulting from the partnership between MTL, a computational design studio, and 3DMZ, an industrial 3D printing hub. The lounge piece was meticulously designed to cater to CLUB3, located in the revitalized Patronaat, a cultural and music venue in Haarlem.

What sets Model.C3 apart is its modular design, offering diverse configurations tailored to different spaces within CLUB3. From a nightclub ambiance to an intimate DJ stage area called the Boiler Stage, and an exhibition space named the Expo, 3D printed lounge piece Model.C3 in CLUB3Model.C3 seamlessly adapts to various functions. Characterized by natural curves and an all-white color palette, the design complements the aesthetics of the venue, serving both functional and aesthetic purposes.

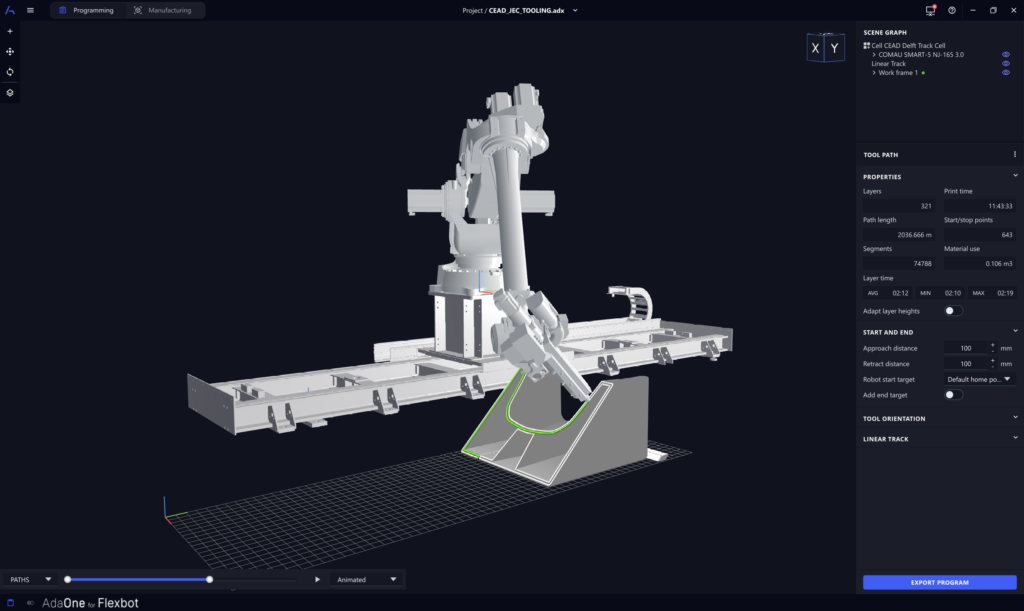

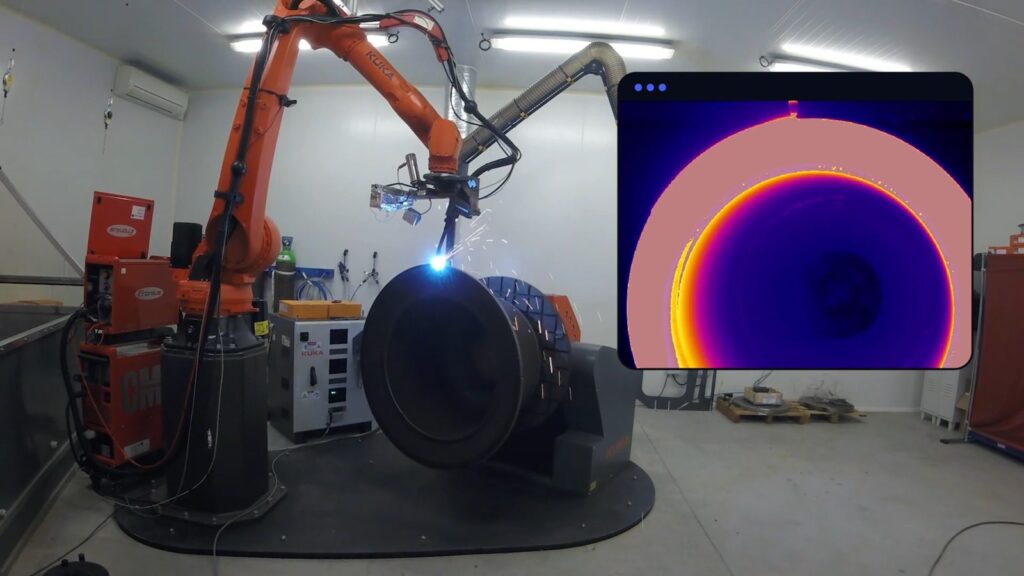

The project marks a significant leap forward in large-scale 3D printing, employing a robotic arm that transcends conventional methods. Unlike traditional layer-by-layer printing, the robotic arm utilized in Model.C3 can print in multiple directions, enabling intricate designs and enhancing structural integrity. The unique shape and robustness of Model.C3 showcase the potential of industrial robotic arms to revolutionize manufacturing across different industries, creating everything from bespoke furniture to building components.

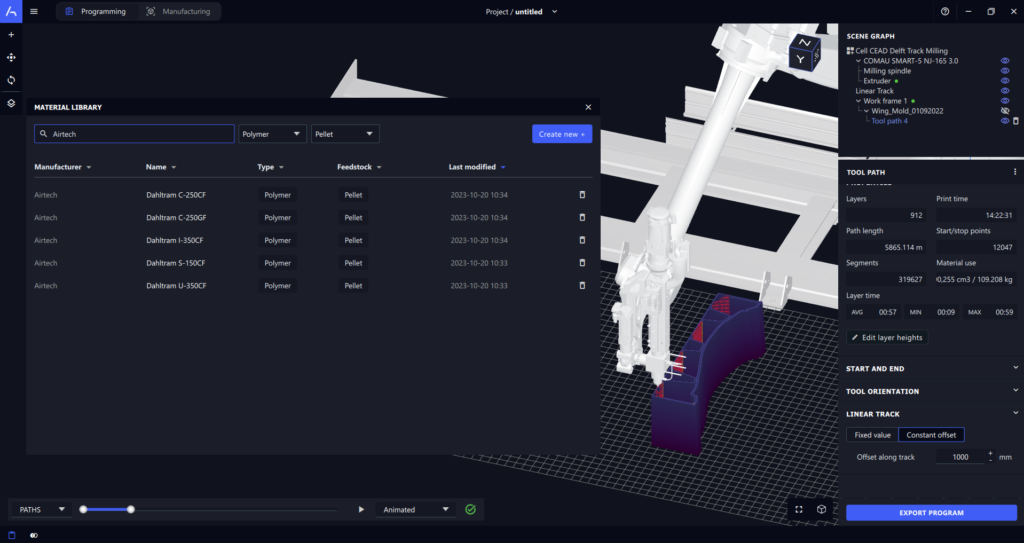

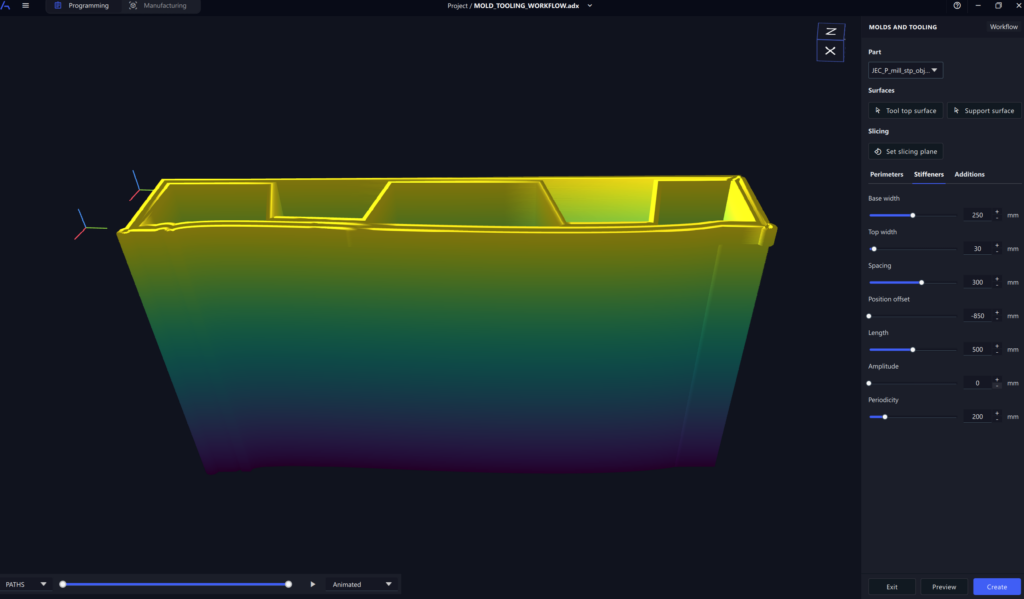

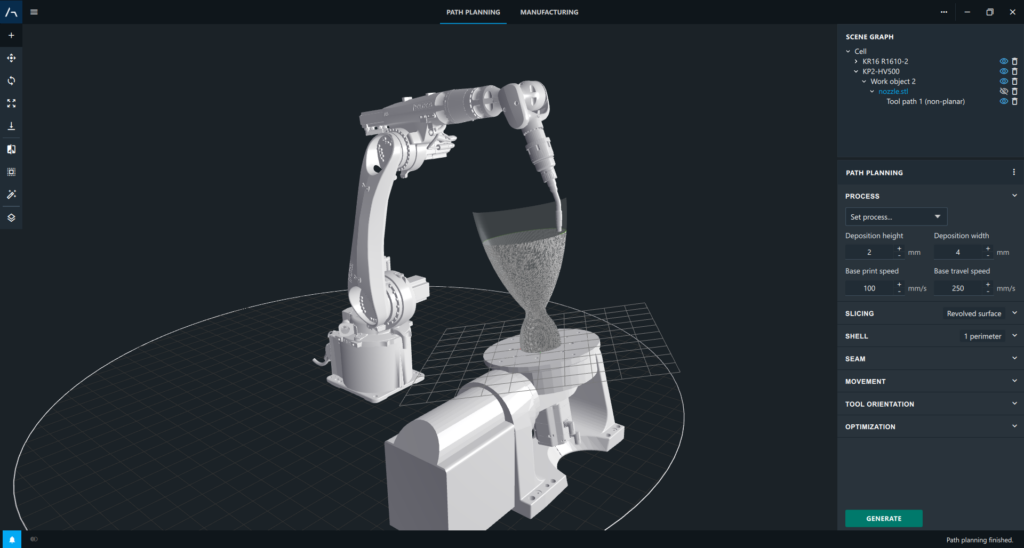

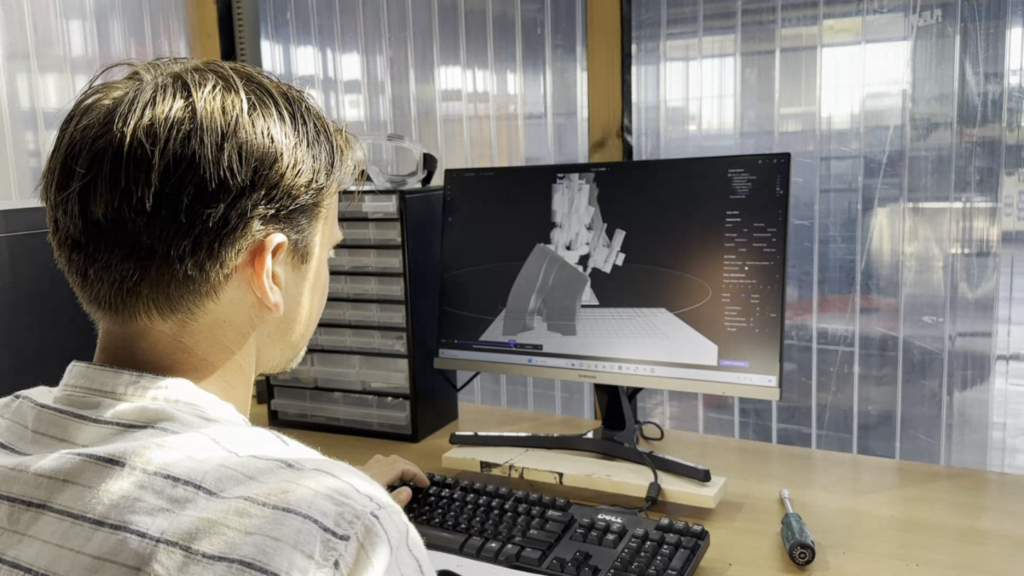

This advanced way of printing the Model.C3 wouldn’t be possible without the right software, which is where AdaOne by ADAXIS plays a crucial role. AdaOne plays a pivotal role in controlling robotic arms for large-scale 3D printing, converting designs into machine-readable code. Its capabilities extend beyond basic functions, encompassing part optimization, path planning, process optimization, robotic simulation, program creation, and process monitoring. In iterative projects like Model.C3, where development stages are crucial, AdaOne’s contribution is integral to achieving success.

In the words of Michael John Sweers, Founder of More Than Layers:

“In the Club3 project, our goal was to push the boundaries of design innovation while ensuring each concept was fully realizable. Traditionally, the journey from design conception to a manufacturable product involves numerous iterations, often requiring us to revisit earlier stages due to manufacturability constraints. This is a time-consuming process and also limits our creative exploration.

AdaOne reformed our workflow, streamlining the transition from initial design to a manufacturable configuration. One of the standout features of AdaOne was its simplification of the slicing process for robotic arms. This allowed our designers to validate their concepts at an early stage, broadening the scope for creative exploration. We could explore a wider range of design options with our client without the usual back-and-forth. It effectively bridged the gap between creativity and practicality, ensuring that our designs were not just imaginative but also fully realizable.

Additionally, manufacturing large, interconnected parts presents its own set of challenges. AdaOne’s capability for quick iterations was crucial, enabling us to adjust the manufacturing process on the fly and maintain high-quality output without compromising on the project’s ambitious design goals.”

Model.C3 is crafted using the newly launched Beon3D material from LyondellBasell, selected for its durability, smooth finish, aesthetic appeal, and recyclability. This choice underscores the commitment to sustainability in the manufacturing process, aligning with the broader industry trend towards environmentally conscious practices.

The Model.C3 project not only represents a milestone in the marriage of design and technology but also emphasizes the transformative role of 3D printing and robotic arms in shaping the future of manufacturing. As industries evolve, projects like Model.C3 pave the way for a new era where creativity and technology converge to redefine what is possible in the world of design and production.