Bayonne, France and Huntington Beach, CA – June 21, 2024 – Airtech Advanced Materials Group, a leader composite tooling and additive materials, and ADAXIS, a pioneering robotics software company, are pleased to announce a strategic collaboration to integrate Airtech’s advanced materials and expertise into ADAXIS’s AdaOne software platform. This partnership aims to provide turnkey programming solutions for end-users, leveraging the full potential of 3D printing technologies.

The collaboration between Airtech and ADAXIS represents a significant advancement in the field of additive manufacturing, combining the expertise of both companies to enhance the quality and efficiency of printed parts. The integration of Airtech materials into the AdaOne platform will introduce specific features designed to optimize the performance of Airtech’s materials, thereby improving the overall quality of printed components.

Key Features of the Collaboration

- Turnkey Programming Solutions:

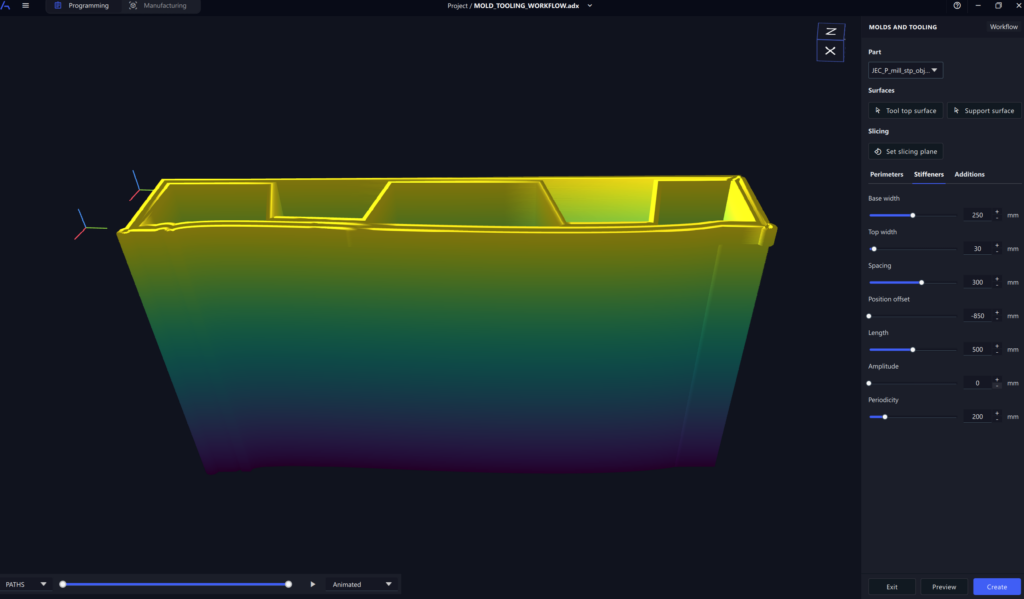

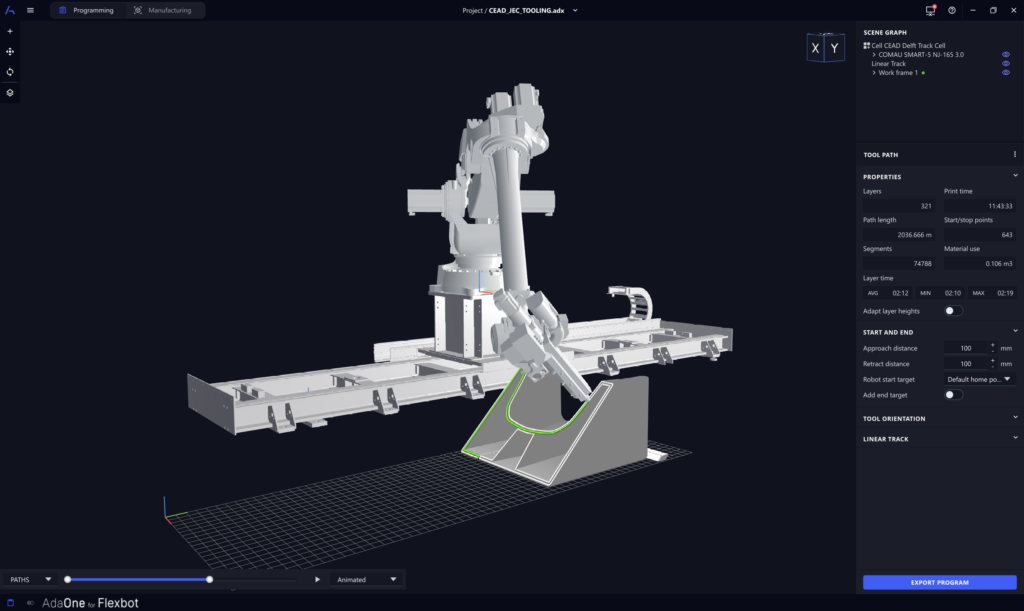

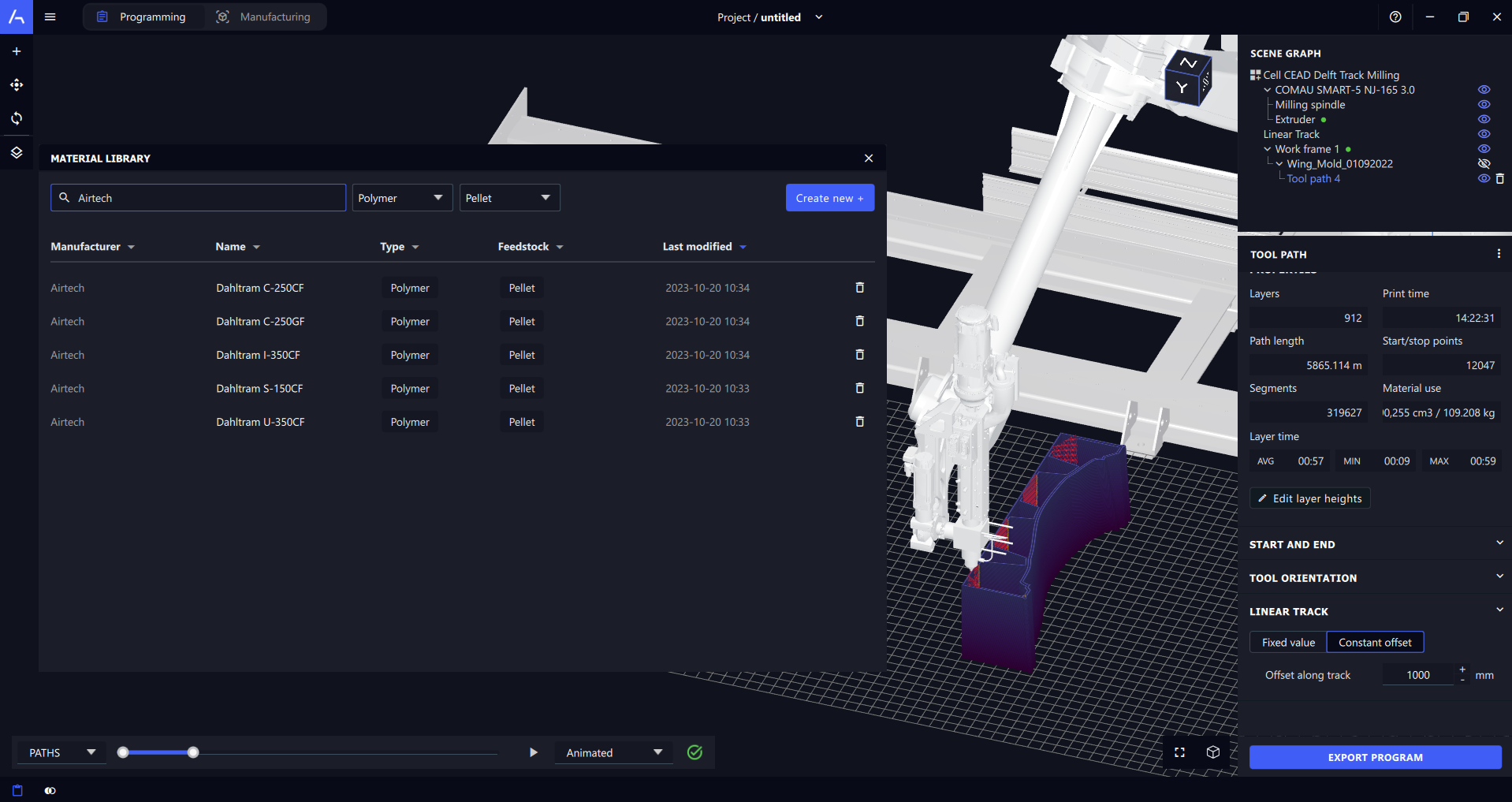

The integration of Airtech materials into AdaOne will enable seamless programming for end-users. This turnkey solution simplifies the process of setting up and using Airtech materials in 3D printing applications. Material profiles will be automatically implemented, setting the correct maximum and minimum layer heights, layer times, and other critical parameters, ensuring optimal results with minimal setup time.

- Material-Specific Enhancements:

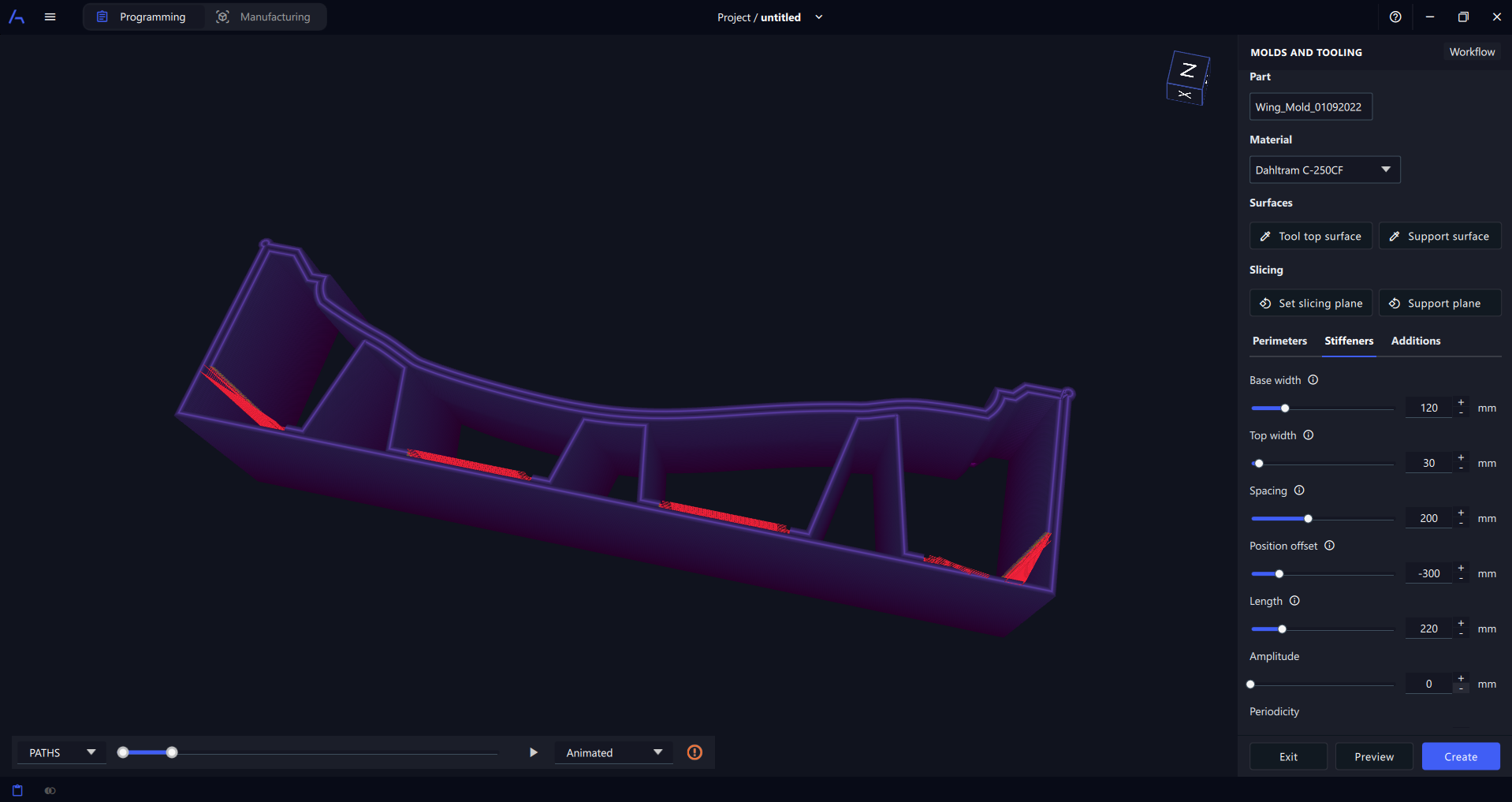

AdaOne will include material-specific algorithms and settings to ensure that Airtech’s advanced composite materials are utilized to their fullest potential. These enhancements will focus on improving the mechanical properties, surface finish, and dimensional accuracy of printed parts. Additionally, the stiffener geometry will be adapted using a genetic optimization algorithm to ensure that each layer has the same layer time, enhancing the structural integrity and uniformity of the printed parts.

- Quality Improvement:

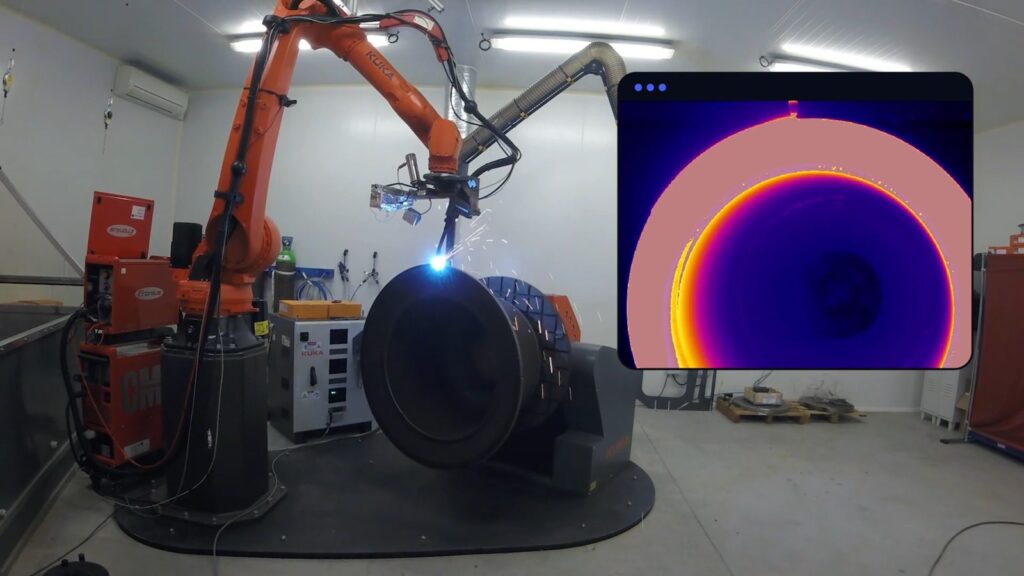

Leveraging Airtech’s expertise in composite tooling and vacuum bagging materials, the collaboration will introduce new quality control features within AdaOne. These features will monitor and adjust printing parameters in real-time to ensure consistent quality throughout the printing process. Furthermore, AdaOne will automatically set the maximum and minimum layer height for planar along curve and sweep operations, optimizing the layer deposition for better print quality and material efficiency.

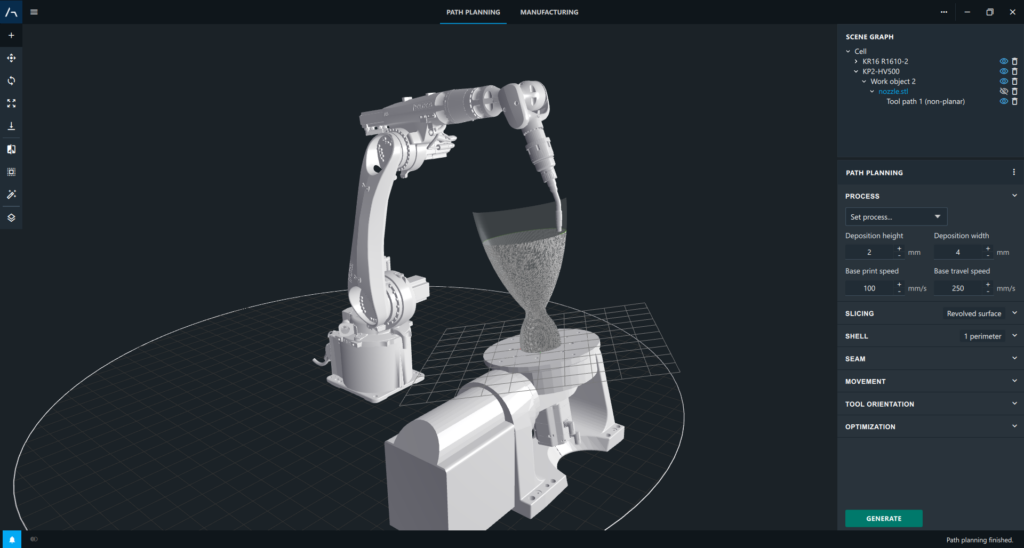

- Expanded 3D Printing Capabilities:

The collaboration aims to fully exploit the capabilities of 3D printing by integrating Airtech’s high-performance materials. This will enable the production of complex geometries and large-scale components that are difficult or impossible to achieve with traditional manufacturing methods.

- User-Friendly Interface:

ADAXIS’s AdaOne platform is known for its intuitive and powerful interface, which will now be enhanced with features tailored for Airtech materials. This will provide users with an easy-to-use solution for programming and executing 3D printing projects with advanced composite materials.

Broader Impact on Industry Partners

This collaboration is a positive development for the existing partners of both companies, including technology suppliers such as Belotti, Caracol AM, CEAD, Dyze Design,Massive Dimension and Rev3rd, as well as end-users like AES, Haddy, and Uni Maine. By unifying technical competencies on a single platform, this partnership facilitates the precise control of pellet-based 3D printing technology, which requires expertise in software, hardware, and materials to maximize its efficiency, profitability, and sustainability for the manufacturing industry.

Quotes

“Our collaboration with ADAXIS represents a major step forward in additive manufacturing. By integrating our advanced materials into the AdaOne platform, we are providing users with the tools they need to achieve superior quality and performance in their 3D printed parts,” said Gregory Haye, Director of Additive Manufacturing at Airtech Advanced Materials Group.

“We are thrilled to partner with Airtech to bring their innovative materials into the AdaOne ecosystem. This collaboration will allow us to offer our users unparalleled capabilities in 3D printing, enabling them to push the boundaries of what is possible with additive manufacturing,” said Emil Johansson, CPO of ADAXIS.