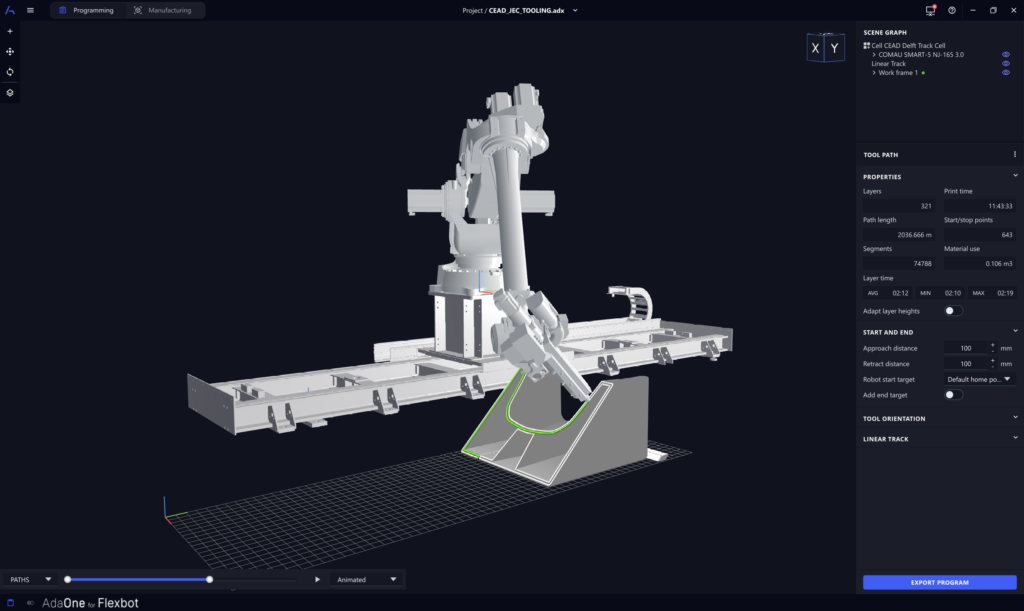

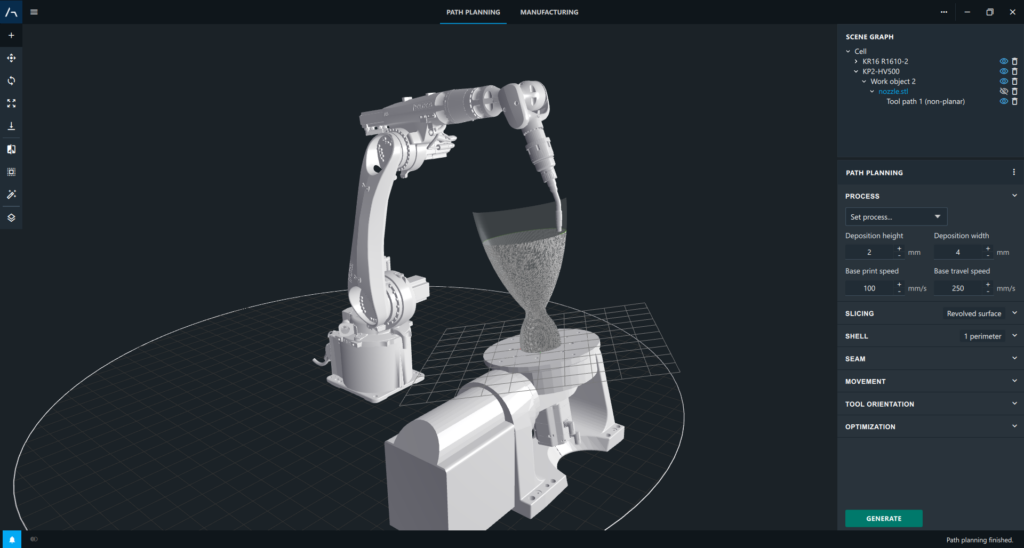

We are excited to announce a groundbreaking collaboration with the University of Maine, showcasing the latest advancements in additive manufacturing through our AdaOne software. Our recent on-site intervention at the University’s Advanced Structures & Composites Center marks a significant milestone in demonstrating AdaOne’s versatility and compatibility with cutting-edge 3D printing technologies.

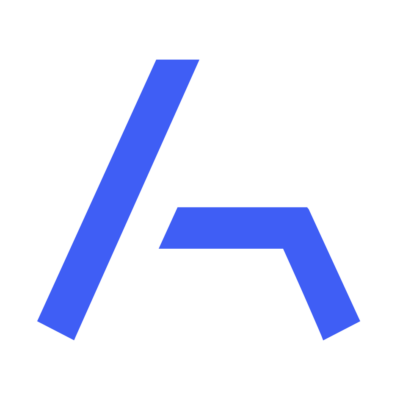

During this collaboration, our team worked closely with the University of Maine to integrate AdaOne with several of their state-of-the-art 3D printers, including the renowned Ingersoll – MasterPrint 3x, the Fortus 900mc 3D Production System by Stratasys, and the Juggerbot3D – Tradesman Series P3-44. This intensive testing phase focused on verifying AdaOne’s compatibility and performance across these diverse systems, highlighting its ability to handle large-scale and high-precision additive manufacturing tasks.

A key feature explored during this phase was AdaOne’s variable deposition capability. This advanced function allows for dynamic control of material deposition rates, a critical aspect in optimizing print quality and efficiency. The tests were conducted using wood fiber composite materials, demonstrating AdaOne’s adaptability to different material types and applications.

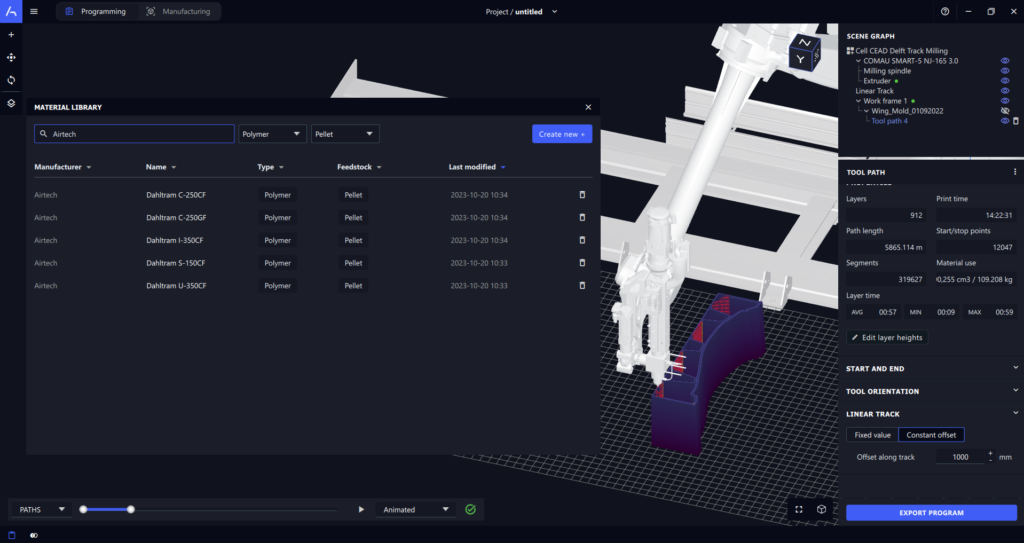

The University of Maine’s Advanced Structures & Composites Center is renowned for its expertise in forest-derived bio-composites and its role in advancing large-scale thermoplastic 3D printing. Their research and development efforts are pivotal in driving innovations in marine, defense, housing, renewable energy, and transportation industries. By collaborating with such a leading institution, ADAXIS reinforces its commitment to pushing the boundaries of additive manufacturing technology.

This collaboration underscores ADAXIS’s dedication to advancing additive manufacturing technology and enhancing its applications in various industries. AdaOne continues to evolve, offering unparalleled support for complex and large-scale 3D printing projects.